Expansion , Dismantling Joints

INTRODUCTION

Metallic Expansion Joints are used in piping system to absorb thermal expansion & vibration while keeping the system pressure. They are a highly engineered product conforming to EJMA standard. We also make MEJ/SSEJ to cater client’s specific need. Under the guidance of this code, Flexocon Engineers Pvt. Ltd. offers a complete range of Metallic Expansion Joints/Stainless Steel Expansion Joints (MEJ/SSEJ) & have the CAD assisted design ability to cater to special needs of customers. They can customized to sizes 18 – 5000 mm, both circular and polygonal, suitable to 1500 degree C,

APPLICATION

Typical applications for metallic expansion joints include petrochemical plant, refineries, power stations, district heating installations, HVAC systems, laundries etc and wherever piping systems or ducts are subjected to movement through the effects of temperature, pressure or external forces. Industrial uses very much encompass power/steel/cement/ fertilizer and other core sectors.

BUILT FOR RELIABILITY

In theory, bellows are one of the most sensitive components of the pipework installation, with thin gauge metal having to withstand the same extremes of temperature and pressure as the pipework installation to which it is fitted. Yet today, modern bellows /expansion joints are considered a permanent part of a pipework installation. Metallic expansion joints require special attention when considering product type, materials of construction, location within the system, anchors, guides and end loads. To ensure «customer satisfaction, Flexocon Engineers Pvt. Ltd. technical support team offers a full design service and on-site technical support to make sure all these conditions are met Materials are AISI 304/316/321,Inconel, Monel, MS etc.

MEETING CUSTOMER REQUIREMENTS

This brochure is intended to give general information concerning the range of expansion joints and services available. Full details of individual products are available on request. Flexocon Engineers Pvt.Ltd. will be pleased to advise on the application and installation of expansion joints to meet customers’ particular requirements.

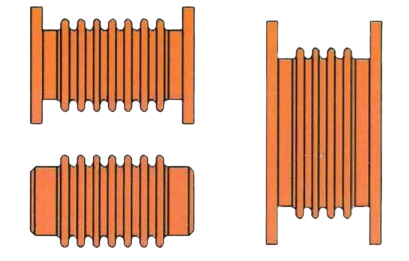

AXIAL BELLOWS

Manufactured from single or multi-ply stainless steel. Available to DIN, EJMA and BSA standard for end fittings, in flanged and weld end assemblies. Four ranges of movement to suit most sizes. Fitted with internal stainless steel sleeves as standard.

UNRESTRAINED DOUBLE BELLOWS

Manufactured in single and multi-ply stainless steel. Suitable for low pressure application to make up both lateral and axial movement, misalignment and vibration. Especially suitable for exhaust systems, turbochargers etc. Available with DIN, EJMA and BSP end fittings, in both flanged and weld end assemblies.

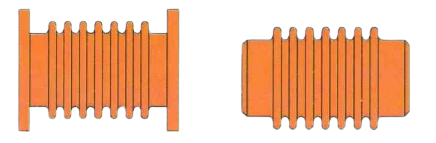

DOUBLE HINGED STAINLESS STEEL BELLOWS

Contains two stainless steel bellows joined by a common connecting pipe. Functions through the angular motion of each bellows in opposite directions to give lateral movement in one plane only. Hinged tie bars absorb thrust from pressure loads, resulting in low anchor forces. The amount of lateral deflection is proportional to the distance between the bellows’ centres.

GIMBALL STAINLESS STEEL BELLOWS

Consisting of a single bellows positioned within the universal joint framework, this unit is designed to resist the thrust from the bellows due to internal pressure. Allows angular movement in any plane. Normally used in pairs or threes or in conjunction with a hinged unit.

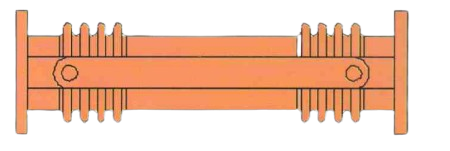

TIED DOUBLE STAINLESS STEEL BELLOWS

Contains two stainless steel bellows joined by a common connecting pipe and incorporating two or more restraining rods having spherical bearings at their end fittings. Its purpose is to absorb two basic movements, angular and universal lateral deflection, or combinations of both. Pressure end loads are contained by the tie rods.

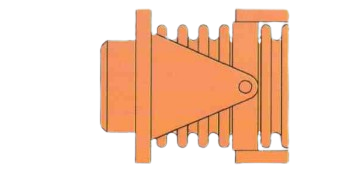

POLYGONAL METALLIC BELLOWS

Polygonal joints are fabricated to tailored client’s needs.

Hydraulic/Vacuum testing determines deformation and bursting pressures. Full X-ray, dye penetration tests are available.

MANUFACTURE

Flexocon stainless steel and other metal bellows are made from tube formed from selected cold-rolled sheet, joined by longitudinal butt welds. The bellows of FLEXOCON, circular and rectangular, are built up from multiple layers. This technically wellconsidered construction has many advantages. For example, much smaller spring forces occur than with single walled expansion joints. Very good flexibility at high pressures is guaranteed (the bursting pressure is at least three times higher than the nominal pressure). And also large movements are compensated despite the extremely compact design. The bellows’ convolutions are formed by cold rolling, a process giving significant lifetime advantages compared with the alternative technique of hydraulic forming.

QUALITY

flexocon Engineers Pvt. Ltd. has quality system based on ISO 9001 2000. This means that the system include all links from selection and application of materials to engineering, production, packaging and site supervision and service. We strive to refine and develop our system through documentation and product compliance to meet specific requirements.

TESTING

The bellows undergo both destructive and non- destructive testing on machines which repeat controlled sets of movements under predetermined conditions of temperature and pressure.

MOVEMENT

Flexocon stainless steel and other metal bellows are made from tube formed from selected cold-rolled sheet, joined by longitudinal butt welds. The bellows’ convolutions are formed by cold rolling, a process giving significant lifetime advantages compared with the alternative technique of hydraulic forming