Filters & Strainers

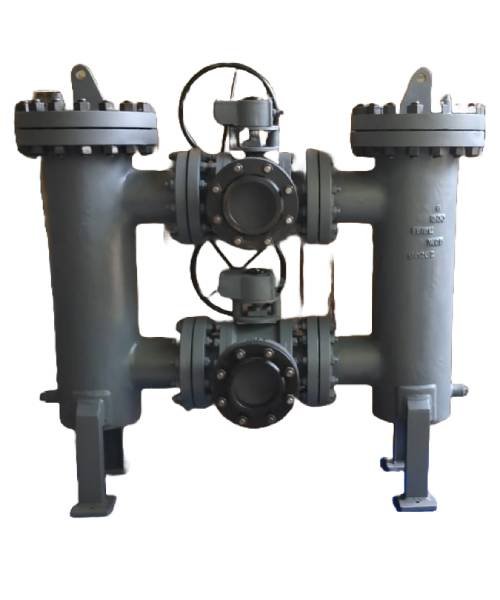

Duplex Auto Self Cleaning Filter-twin 3 way valve design

· Filter unit comprises of two filter chambers, which are connected to

each other by means of Pneumatic Operated Three Way Ball Valve each

at Inlet and Outlet.

. Liquid to be filtered enters through the inlet connection and passes

through the Filter Element.

.Solids larger than the selected micron spacing are either retained on

the outside of the filter element or dropped into the filter chamber sump

. Suitable for large volume and fine filtration up to 30 microns available

with single or multi elements in body carbon steel, SS 304, 316, 316L or

any other alloy steel material.

Conical Type Strainer:

Conical Strainer consists of suitably designed element directly housed in a pipeline between flanged connections. Conical strainers are usually used in batch operations where the liquid flow may be interrupted periodically for cleaning and maintenance.

Conical strainer elements are in fabricated types. Conical strainers are fabricated and designed as per ASME Section VIII Division 1. Sizing is based on the required filtration area for the given flow rate and the maximum allowable pressure drop. Various parameters like viscosity, density, operating temperature, degree of filtration determines the selection of a particular design of strainer element.

Conical Type Strainer:

Conical Strainer consists of suitably designed element directly housed in a pipeline between flanged connections. Conical strainers are usually used in batch operations where the liquid flow may be interrupted periodically for cleaning and maintenance.

Conical strainer elements are in fabricated types. Conical strainers are fabricated and designed as per ASME Section VIII Division 1. Sizing is based on the required filtration area for the given flow rate and the maximum allowable pressure drop. Various parameters like viscosity, density, operating temperature, degree of filtration determines the selection of a particular design of strainer element.